PROJECT

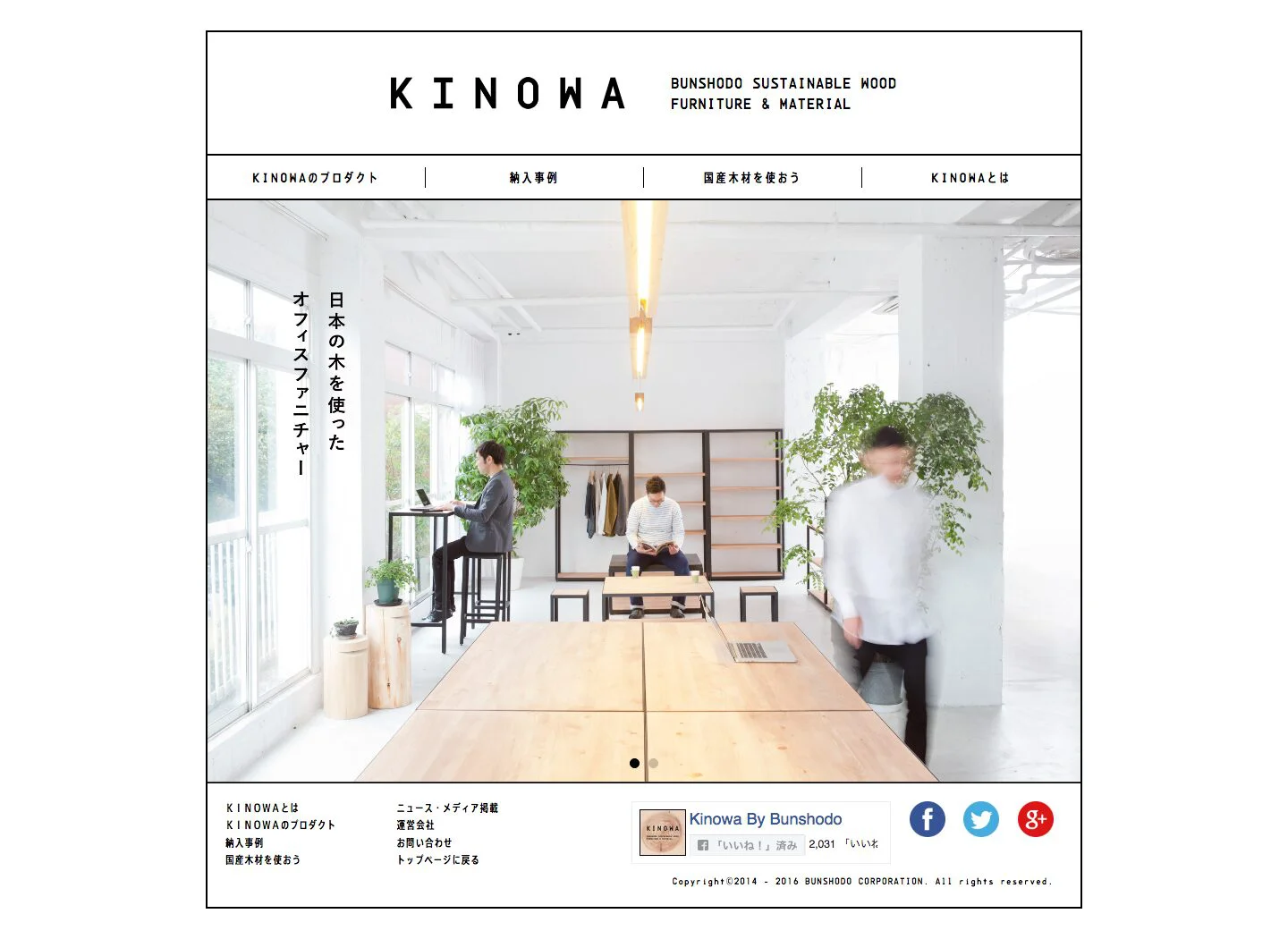

KINOWA

Furniture brand promoting Japanese thinned wood through minimal processing that amplifies timber value. DFA Design Award Gold winner.

WHY

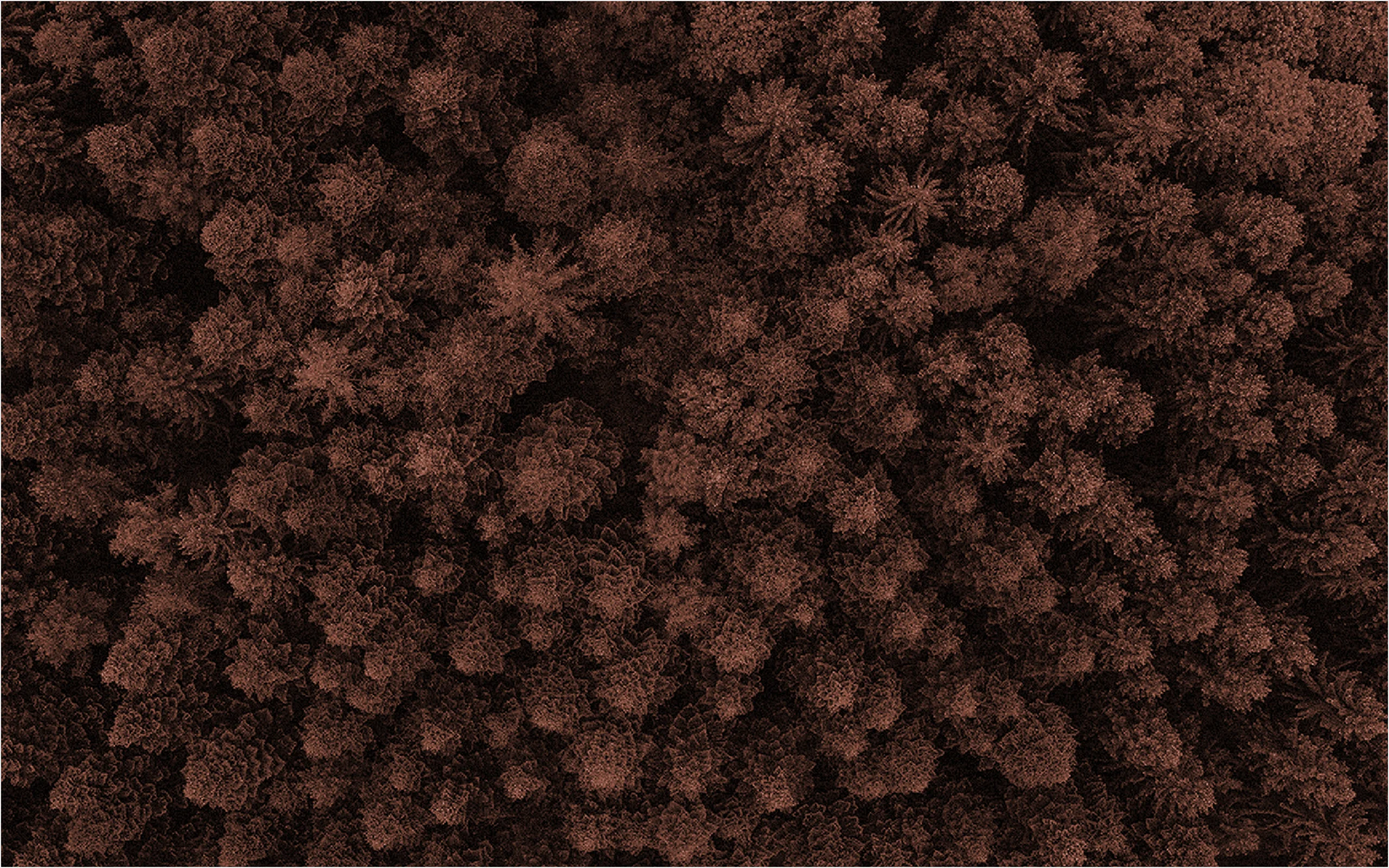

To restore

forest biodiversity.

After the war, forests in Japan were cut down excessively due to fuel and demands in building materials. After logging, large-scale afforestation centered on cedar and Japanese cypress was carried out because of its new policy. However, the liberalization of wood imports began in 1964, where demand shifted to inexpensive foreign-made materials. Currently, some of the artificial forests that account for about 40% of the Japanese forests are left untreated despite the fact they are in the thinning period. Some have resulted in the loss of forest biodiversity. It is also said the level of hay fever is causing people more than usual to suffer.

Timber self-sufficiency rate and demands/supplies in Japan

Comparison between forestry revenues and initial forestation costs

HOW

A furniture brand

using thinned wood

as it is.

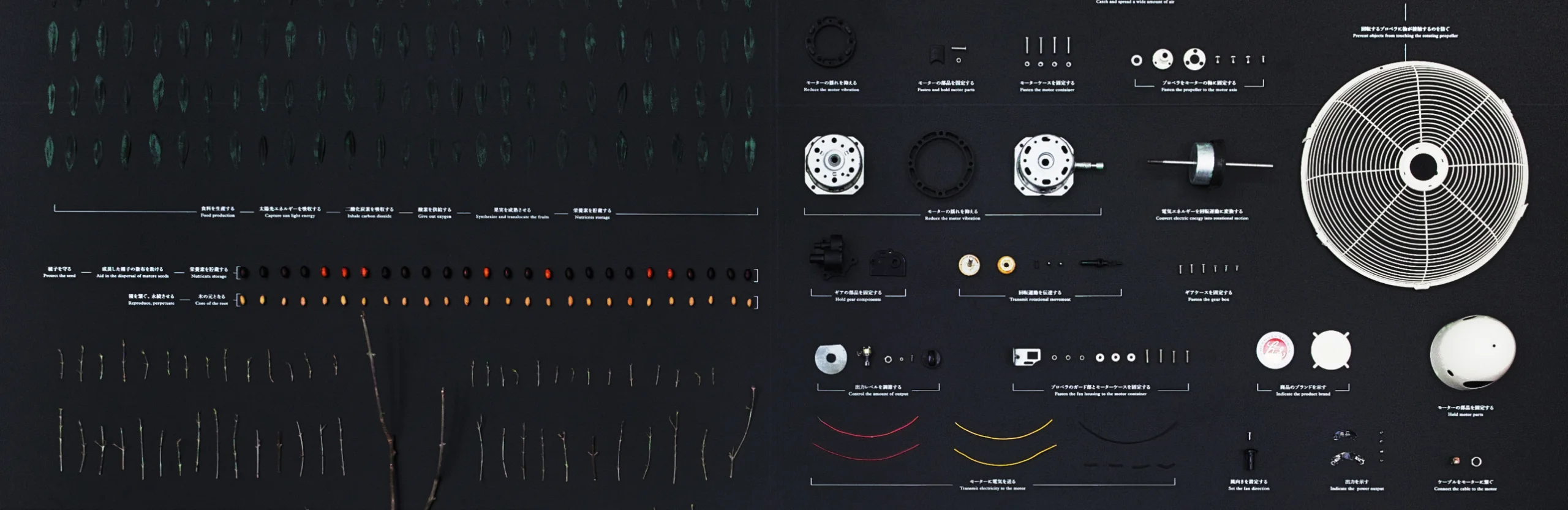

To regain a rich ecosystem, it was necessary to prepare a situation where domestic timber could be used daily. We decided to launch a furniture brand that uses thinned wood as it is, together with Bunshodo Co., Ltd., who constructs offices/shops, and also sells furniture. “KINOWA” has a mechanism to lower the hurdle of using timber, by releasing production drawings of each product as an Open Source, to use sustainable furniture manufacturers, not only professional contractors.

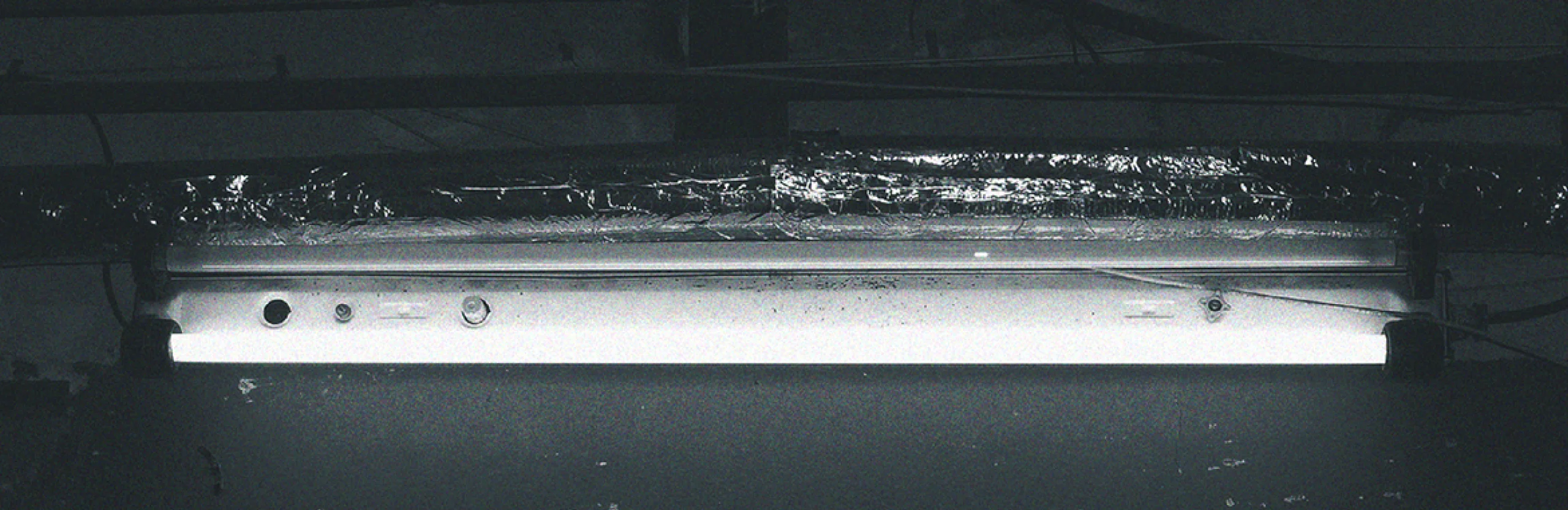

KINOWA BEAM is a luminaire with LED lights, embedded within a bar of barely tampered cedarwood. Based on the concept idea of carbon offset, we produced a design that requires little woodwork, as with other KINOWA products, producing as little waste as possible. To make the most of the cracks that occur from dryness, we embedded an LED light inside, to acquire its highest form in texture and presence. This product won Gold at the DFA Awards.

By using logs of thinned timber, squared bars, and board materials as it is, reducing any complicated process. We made it possible to incorporate Japanese trees easily into our lifestyle at reasonable prices.

WILL

Through Open Source,

spread new ideas

for the future of forestry.

Since the beginning, KINOWA has been using thinned timber from Okayama prefecture in Nishawakura village. Now, efforts in using thinned wood from other areas are also being used based on our Open Source drawings. KINOWA’s activities have gradually expanded, such as delivery services to companies and offices of organizations that sympathize with the brand’s philosophy. However, while Japanese wood self-sufficiency rates are on its way to recovery, most are still dependent on imported materials. We are now looking for others who want to participate in this initiative. Please download production drawings from the link below of each KINOWA product, and become a part of the community.

INFORMATION

- What

- KINOWA

- When

- 2013

- Where

- Japan

- Client

- Scope

- Product / Graphic / Photograph

CREDIT

- Art Direction

- NOSIGNER (Eisuke Tachikawa)

- Product Design

- NOSIGNER (Kunihiko Sato, Sui Fujikawa)

- Graphic Design

- NOSIGNER (Takeshi Kawano)

- Photo

- Masaharu Hatta, Kunihiko Sato